Let’s start with Crawlspace Basics

A Vented crawlspace is built with multiple foundations vents located in the perimeter walls of the crawlspace. These vents allow outside air into the crawlspace area. The traditional school of thought was by venting with outside air that would help control moisture and improve the overall air quality within the space. However, wall-vented crawl spaces can cause moisture buildup and other complications in households, especially in the Southeast.

An Unvented (Conditioned) crawlspace does not have vents – it is sealed against outside air infiltration. Think of the crawlspace as another room in your home – like a basement.

One of the most common terms used for creating an unvented crawlspace is “Encapsulation”. This type of crawlspace is insulated at the perimeter walls and not the crawlspace ceiling. To protect from ground generated water vapor a true “vapor barrier” must be installed. The vapor barrier must be properly sealed at the seams, edges, etc. so that vapor cannot penetrate into the crawlspace. You can “condition” the space by installing a properly sized dehumidifier.

The principal disadvantages of a vented crawl space over an unvented one are that (1) pipes and ducts must be sealed and insulated against heat loss (cooling loss in the summer) and freezing, (2) a larger area (the crawl space ceiling typically is larger than the area of the crawl space walls) usually must be insulated, which may increase the cost, (3) under hot humid conditions warm humid air circulated into the cool crawl space can cause excessive moisture levels in structural wood components (especially floor joists) that can cause mold and decay, and (4) an airtight, continuous thermal envelope at the crawl space ceiling is very difficult to achieve in practice.

· Credits: DOE Building Foundations Handbook, North Carolina Advanced Energy Corporation

Vapor Retarder vs. Vapor Barrier

A true vapor barrier must have a vapor permeance rating of less than .001. Typical builder grade 6ML black poly does not meet this requirement. It’s a vapor retarder not a vapor barrier.

Typical builder grade 6ML black poly is made from recycled content. This may sound environmentally friendly, but each time polyethylene is recycled, reground, etc. it loses its original performance characteristics. It will break down, turn brittle and not perform its role as a vapor retarder. It will need to be replaced several times during the life cycle of a home’s crawlspace.

Crawlspace Insulation

New Construction (Building Permit): First – always refer to the local building codes to determine what edition of the International Building Code they have adopted. For our area you have typically have a couple of options. Insulate between the floor joists of the crawlspace ceiling to R19 or insulate the perimeter walls of the crawlspace to R10.

There are several methods that could be used to achieve either of these requirement’s – the most common is R19 fiberglass batts between the floor joists of the crawlspace ceiling. You must present an insulation certificate that states the R-values of what was installed prior to receiving a Certificate of Occupancy.

Retrofit: There a couple ways to change or upgrade your existing insulation. You can DIY the install or hire a professional insulation install company. Either way, since a building permit is not involved, you may decide to install as you see fit. However, some words of caution, if you do not perform the installation to current building code standards this could really cause a problem down the road. An issue will most definitely arise if you decide to sell your home. Most every home sale requires a home inspection. Home inspectors are very up to date on current code requirements and will most certainly note any deficiency in the insulation on their reports. It will be a condition you must correct prior to the home selling.

Our Systems

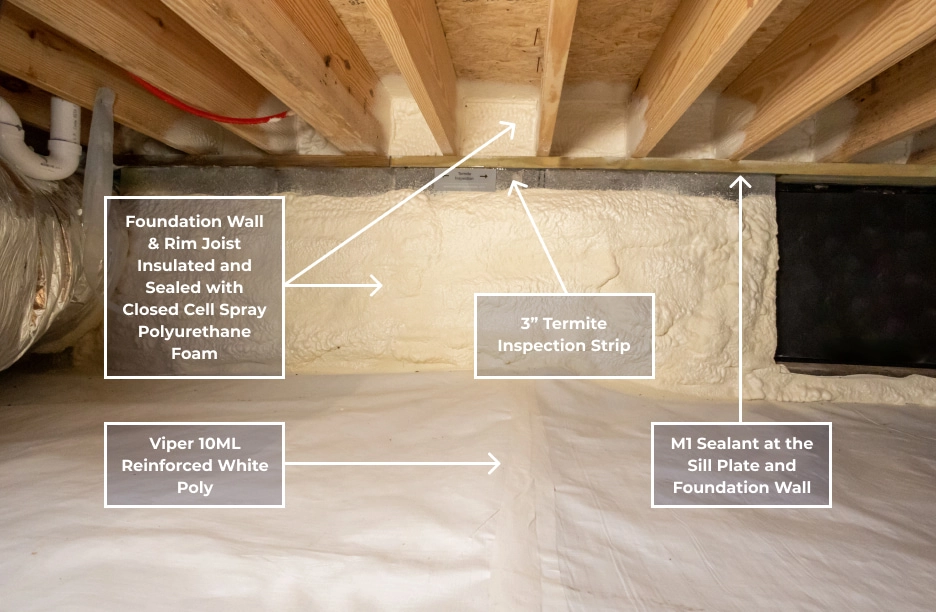

Encapsulation

The ultimate non-vented crawlspace system. Vapor Barrier will be the Viper CS 10 ML – Reinforced: White

Foundation vents will be sealed and insulated with Closed Cell Polyurethane Spray Foam. Exterior walls and rim joist of the crawlspace will be insulated and sealed with Closed Cell Polyurethane Spray Foam.

Vapor Retarder:

A Standard Builder Grade Vapor Retarder System using Black 6ML Poly. The 6ML Vapor Retarder will be installed over the floor of the crawlspace and approximately 10″-16″ up the exterior perimeter walls of the crawlspace.

The Vapor Retarder will be mechanically fastened to the exterior perimeter walls for long term security. All seams will be taped using Black Seam Tape.

Viper Reinforced Vapor Barrier

6.5 ML

Viper Reinforced 6.5ML White is a true Vapor Barrier System. The Viper 6.5ML Vapor Barrier will be installed over the floor of the crawlspace and approximately 10”-16” up the exterior walls of the crawlspace.

The Vapor Barrier will be sealed to the exterior perimeter walls of the crawlspace with Viper Double Bond Butyl tape. Once sealed to the exterior perimeter walls the Vapor Barrier will be mechanically fastened for long term security. All seams will be taped using a white Seam Tape approved for use in a crawlspace environment.

Key Performance Characteristics:

- Permeance Rating – ASTM E96: .0095 Perms

- Puncture Resistance – ASTM D6241: 255 LBF

- Tear Resistance – ASTM D7004: 117 LBF

Viper CS 6.5ML Crawlspace Vapor Barrier warranty: ISI Building Products warrants, to the original Purchaser, crawl space vapor barriers manufactured by the Company. Viper CS will, for a period of 25 years, be free from defects in material and workmanship, under normal and proper use, storage, and operating conditions. Warranty details available upon request.

10 ML

A premium 10ML Vapor Barrier System featuring the Viper Reinforced White 10ML Poly. The Viper 10ML Vapor Barrier will be installed over the floor of the crawlspace and approximately 10″-16″ up the exterior perimeter walls of the crawlspace.

The Vapor Barrier will be sealed to the exterior perimeter walls of the crawlspace with Viper Double Bond Butyl tape. Once sealed to the exterior perimeter walls the Vapor Barrier will be mechanically fastened for long term security. All seams will be taped using a white Seam Tape approved for use in a crawlspace environment.

Key Performance Characteristics:

- Permeance Rating – ASTM E96: .0016 Perms

- Puncture Resistance – ASTM D6241: 626 LBF

- Tear Resistance – ASTM D7004: 138 LBF

Viper CS 10ML Crawlspace Vapor Barrier warranty: ISI Building Products warrants, to the original Purchaser, crawl space vapor barriers manufactured by the Company. Viper CS will, for a period of 25 years, be free from defects in material and workmanship, under normal and proper use, storage, and operating conditions. Warranty details available upon request.

Why Viper for your Crawlspace Vapor Barrier?

The manufacturing of Viper CS starts with top-quality virgin resin which contains no recycled content. The resin then is converted into strands of polyethylene and formed together with a very tight hatch style pattern. The membrane that has been cross-woven is completed by coating the two sides with proprietary extrusion layers.

Viper CS is not like other products which contain reground or recycled plastic material as it is puncture and tear resistant when being installed and it won’t break down over the duration of time following installation.

![]()

![]()

![]()

![]()

![]()

![]()

For a clean and fresh look in your crawl space, Viper CS comes with a brilliant bright white color. This impressive vapor barrier is able to prevent detrimental effects that come from moisture, mold, mildew, and radon.

Having Viper CS installed correctly is essential when it comes to the long duration of powerful performance encapsulation projects. In order to provide the finest professional grade installations and best practices, ISI currently supports a distribution network as well as annual training opportunities.

ISI Building Products

Lifetime Warranty

For Viper CS Crawl Space Vapor Barriers